Glass Flooring Information & Facts

Glass Flooring Information & Facts

Why choose Jockimo glass flooring?

Corporate Background

Jockimo, Inc. has been a leader in the glass flooring market for almost 2 decades. During that time, we have witnessed glass flooring’s popularity substantially grow in the commercial and residential markets. We have completed many projects - both commercial and residential.

Some of our notable flooring projects include:

- 911 Memorial Museum

- Oklahoma City Federal Building

- Frank Ghery - Panama Museum Project

- Chicago Transit Authority

- Lincoln Center

- Biltmore Estate

- Miami International Airport

- Miami Dade Community College

- 9/11 Museum in NYC

- Observation Deck of Freedom Tower

- Google HQ

- Avengers End Game movie

Corporate Expertise

Both Igor and Tim were on the sub-committee that wrote the Glass Flooring ASTM. They have written articles for CSI, glass and interior design magazines, and have spoken at the NGA Glass America Trade Show.

Anti-Slip Qualifications.

Our product is tested in wet and dry conditions.

See the Jockimo Anti-Slip Design Guide, available upon request. Our #1 walking surface, GlassGrit™, has passed five test protocols. We use tests that are recognized internationally. And finally, we have the test reports to prove our claims. Igor says that in the Air Force they have a saying: "In God we Trust, all others bring data."

Effectively Transparent Glass Floors.

We are the only company that has two products that are effectively transparent with anti-slip features. GlassGrit™ Crystal Clear anti-slip feature is rated for wet and dry conditions. GlassSculpt™ anti-slip feature is rated for dry conditions only.

Lamination

We utilize polylam (excellent adhesion performance), SGP, and pvb. For exterior installations we advocate the use of polylam and SGP.

Anti-scratch

Jockimo has an anti-scratch feature called J-Glass™. JGlass™ can be applied to the entire family of Jockimo anti-slip glass flooring surfaces (as well as our ThickGlass™ counter tops and vertical cast glass products). Click the image at right to watch our JGlass™ anti-scratch demo.

Engineering (see sample report)

We use finite element analysis to verify each project's structural safety. This engineering analysis report provides assurance to all parties that the glass is indeed safe and meets and/or exceeds ASTM standards.

Structural Support (see pdf)

This document explains how the panel should be supported. It also explains what silicone and setting blocks should be used.

Metal

We have trusted strategic partners to provide metal supports and skylights. (See the tab below to learn more about this subject.)

Installation

We have a network of glass flooring installers to assist our customers.

Wide Product Selection

We have the widest product selection in the industry. We have kiln fire, ceramic frit, and acid etch products.

Jockimo vs. the "competition"

Feature/Service |

Jockimo |

“competition” |

| Meets ASTM safety requirements | Y | N |

| Designs and produces their own glass | Y | N |

| Standard and custom sizes available | Y | N |

| Integrated LED lighting | Y | N |

| Adheres to ADA requirements | Y | N |

| Tested to meet international slip resistance requirements | Y | N |

| Anti-scratch surface available | Y | N |

| 4 anti-slip walking surfaces available | Y | N |

| SentryGlas interlayer | Y | N |

| Fully thermally isolated frame | Y | N |

| Fully engineered | Y | N |

| Walking surfaces rated for wet AND dry conditions | Y | N |

| In business producing and providing Glass Flooring for longer than 3 years | Y | N |

| Ex customer of Jockimo | N | Y |

| Ships internationally | Y | N |

| First in industry to provide a stepped insulated glass unit | Y | N |

| Aluminum AND Steel frames | Y | N |

| Walkable Skylights | Y | N |

| Glass Flooring Insulated Units | Y | N |

History & Myths

Many people think that glass flooring is a new product - the "latest hot new trend". Glass floor panels "back in the day" were typically poured cast glass 1"+ thick annealed glass and not tempered or laminated for safety. These 90 year old plus installations are now being replaced by modern glass flooring systems due to the fact that certain support structures are deteriorating and the difficulty in replacing cracked or broken cast glass panels. The life span of a glass floor based on this fairly long history is expected to well exceed 50 years of service.

Many people think that glass flooring is a new product - the "latest hot new trend". Glass floor panels "back in the day" were typically poured cast glass 1"+ thick annealed glass and not tempered or laminated for safety. These 90 year old plus installations are now being replaced by modern glass flooring systems due to the fact that certain support structures are deteriorating and the difficulty in replacing cracked or broken cast glass panels. The life span of a glass floor based on this fairly long history is expected to well exceed 50 years of service.

The second myth in regard to glass floor panels is that the walking surface of glass floors is slippery. This is simply not the fact. Jockimo was the first company in the industry to meet worldwide (US, UK, EU, AU) anti-slip standards with our exclusive products.

The final myth is regarding strength. Are glass floors strong? Will they hold pedestrian traffic? Absolutely! Glass floors should be engineered to hold pedestrian traffic 100 to 150 lbs per square foot. Additionally, the analysis (we strongly recommend finite element analysis) should take into consideration that the glass must be partially compromised (broken) and yet still hold the load. Today the ASTM and other standards dictate that glass be produced to minimize potential liabilities and in turn be safe for all. Jockimo was a contributing member to the ASTM glass floor development committee where standards were developed for all to follow in the producing of glass floors and glass stair treads. This new standard dictates that all glass floor panels should be laminated for safety.

Knowledge is Power/ Rules of Thumb

There is an old saying, "knowledge is power," and that sums up the philosophy here at Jockimo. We believe that in order to choose the very best glass flooring and glass treads/steps, you need to learn as much information as possible about the product. Unfortunately due to the popularity of walkable glass products there are now many "experts" touting their vast experience producing glass flooring products. We have come to learn that like buying insurance, you need to be careful and our goal is to be as transparent and provide the safest possible solution for our customers.

There is an old saying, "knowledge is power," and that sums up the philosophy here at Jockimo. We believe that in order to choose the very best glass flooring and glass treads/steps, you need to learn as much information as possible about the product. Unfortunately due to the popularity of walkable glass products there are now many "experts" touting their vast experience producing glass flooring products. We have come to learn that like buying insurance, you need to be careful and our goal is to be as transparent and provide the safest possible solution for our customers.

Jockimo "rules of thumb" when considering glass flooring:

- Safety should be your #1 concern when discussing glass flooring.

- Only properly tested anti-slip surfaces should be used. (Request documentation to verify authenticity and be careful on this one - it is very losey goosey with some "competitors".)

- Work only with an experienced manufacturer/supplier. Ask for technical data and references and remember - safety is of #1 importance.

- A structural engineer must be used to determine the make up of the glass panels. (The engineering report covers liabilities and it helps regarding the re-selling of a property.)

- Daylighting – glass should allow for the maximum amount of light to pass. (*The use of opaque anti-slip material should be avoided.)

- Privacy – in public applications an obscure product should be used so improprieties do not occur. This obscure product should still allow for light to pass through the glass.

- Product should be durable and easy to maintain and provide an anti-scratch option.

Popularity

Oklahoma City Federal Building

Oklahoma City Federal Building

Why are glass floors and glass treads so popular now?

- Daylight Harvesting is the practice of capturing light from an exterior source, by making adjacent walls and floors transparent so that light can travel freely across room interiors. More and more designers are wanting daylight harvesting in their projects and glass flooring is the perfect product! The glass-flooring product should allow for the maximum amount of daylight to pass. Therefore, the use of opaque anti-slip material should be avoided. Daylight harvesting reduces electrical consumption and provides access to nature by the occupants of a building. Numerous studies have proven that human performance is increased when exposed to daylight.

The intent of the Indoor Environmental Quality Credit 8.1: in the USGBC LEED ® V3 reference guide is to provide occupants with a connection between the indoors and the outdoors. Using glass-flooring panels for daylight harvesting is a means to create transparency for this important environmental strategy. - Safety is of the utmost importance and at Jockimo we engineer the glass specifically for your project with your project's specifications. This allows us to provide you with the safest possible glass for your project. Jockimo is the first manufacturer to provide you with an engineering analysis pdf of your glass project from our structural engineer - who is a glass specialist. This is VERY important and will be helpful for the owner and GC when discussing with building inspectors. (There are many structural engineers in the world but not many that are experts on glass. We recommend that only a structural engineer specializing in glass be used.) ALL of the glass that Jockimo produces meet the latest ASTM glass flooring standards. (The engineering report covers liabilities and it helps regarding the re-selling of a property.)

- Beauty - Everyone loves glass and walking on Jockimo glass flooring is a new unmatched experience. Not only is our glass strong, safe, and provides a great deal of daylight harvesting to spaces but it is absoultely beautiful. All Jockimo projects are produced specifically for each project and that allows us to provide you with the highest quality product available in the industry. Jockimo offers an effectively transparent glass flooring options that has wet and dry anti-slip ratings.

- ADA Standards - As well as meeting international requirements for slip resistance, Jockimo also offers an ADA (Americans with Disabilities Act) required contrasting strip on the nosing of stair treads and landings. Jockimo is the first glass flooring manufacturer to offer this patent pending product. Available in various colors or patterns

- Modesty - When specifying a glass-flooring product, designers should review the privacy aspects of the installation. In public applications an obscure product should be used so that improprieties do not occur. This obscure product should still allow for light to pass through the glass. Jockimo offers both transparent and translucent options to fit most every project requirement. At Jockimo we offer many solutions that provide modesty as well as safety!

- Longevity - Jockimo has been producing glass flooring longer than anyone in the industry.

Customization

Customization is our specialty. We can provide various glass colors, lamination colors, paints, silvering, custom frost, special lamination inter-layers including our ImagenGlass™ or DichroGlass™ as well as standard and custom Jockimo cast glass textures. We would love to develop a custom product for you using your design/ideas or one of ours!

Jockimo was the first company in the industry to receive UL and NFSI certification on its glass flooring products. We are also the first company in the industry to meet worldwide (US, UK, EU, AU) anti-slip standards with our exclusive products.

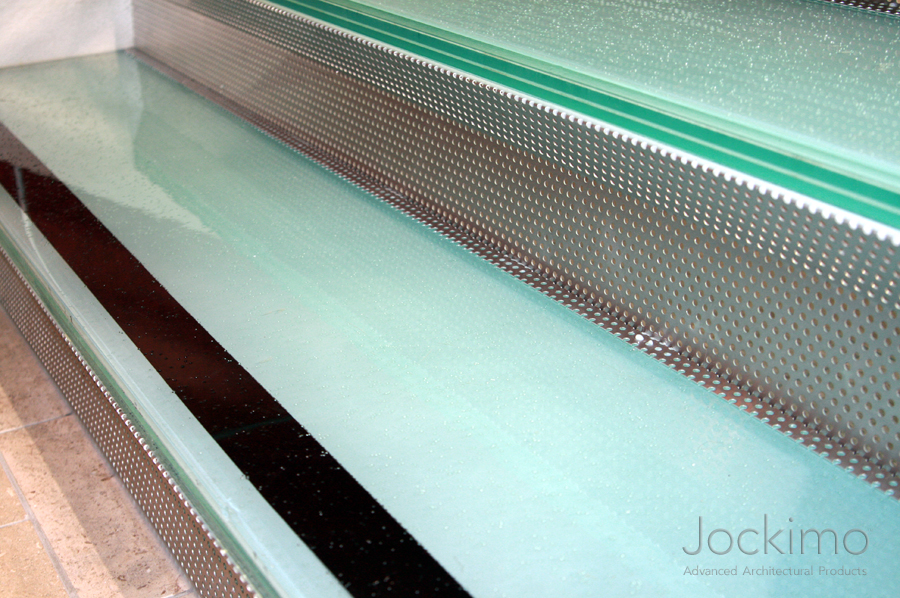

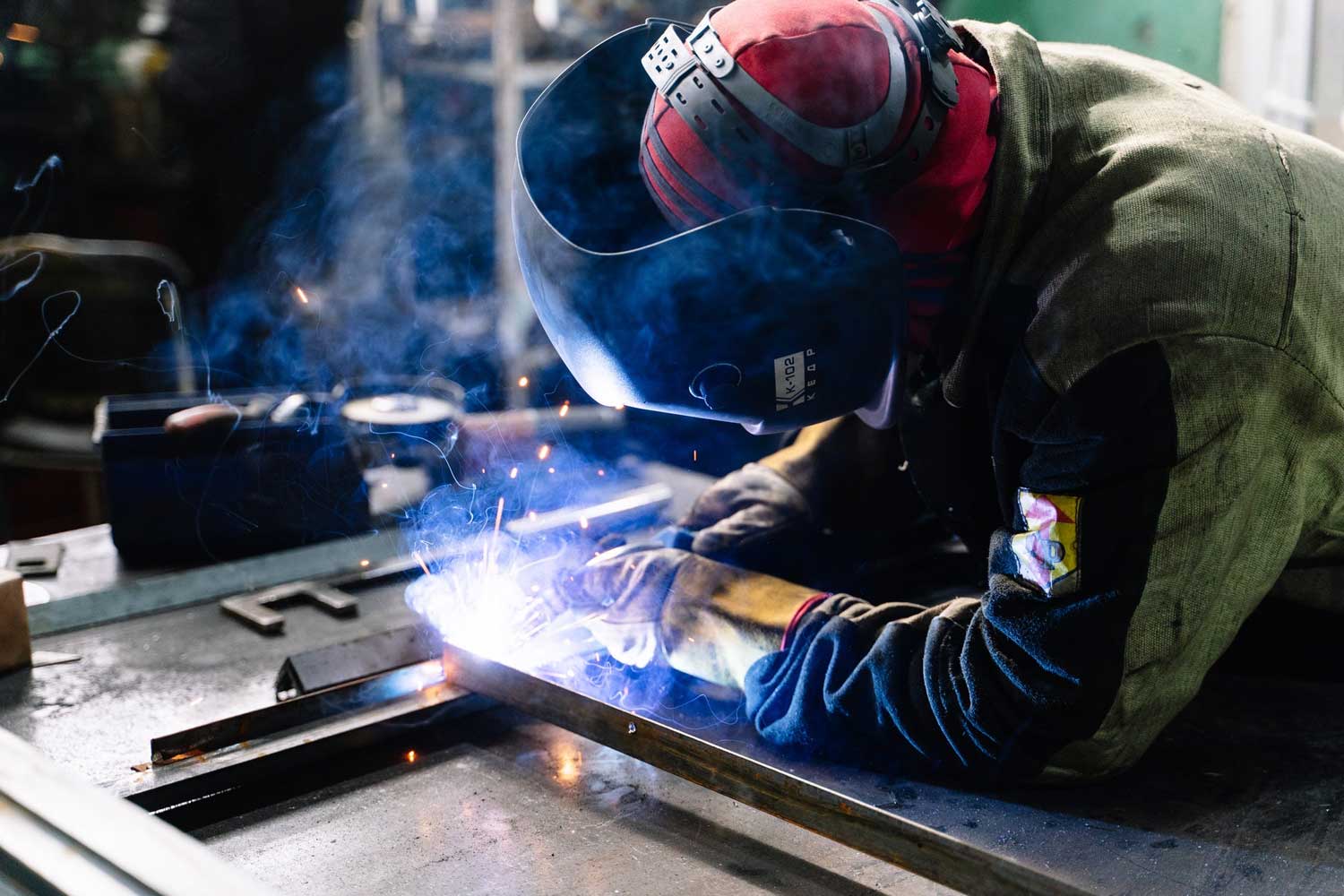

Metal Support System

Jockimo Glass Flooring Metal Support being assembledAt Jockimo we are glass experts - we know glass and we do glass very well. We have been producing glass flooring longer than anyone - for over 18 years. (Yes we produce our own glass. We do not buy and resell an untested and non ASTM compliant or untested glass like so many others in the industry.) We have developed 4 distinctive anti-slip glass walking surfaces that are superior to any other glass products on the market - exceeding international slip resistance ratings and rated for dry AND wet conditions.

Jockimo Glass Flooring Metal Support being assembledAt Jockimo we are glass experts - we know glass and we do glass very well. We have been producing glass flooring longer than anyone - for over 18 years. (Yes we produce our own glass. We do not buy and resell an untested and non ASTM compliant or untested glass like so many others in the industry.) We have developed 4 distinctive anti-slip glass walking surfaces that are superior to any other glass products on the market - exceeding international slip resistance ratings and rated for dry AND wet conditions.

We are able through our strategic partners to provide a superior structural support system made of either aluminum or steel. Our partner has been producing structural metal framing for skylights for over 45 years and has a great deal of experience with thermally broken walkable skylights. They provide the highest quality support system that we have ever seen - and in conjunction with our Jockimo glass we are able to provide a superior solution to our customers.

“Whatever you do, do it well. Do it so well that when people see you do it, they will want to come back and see you do it again, and they will want to bring others and show them how well you do what you do.” - Walt Disney

"But Jockimo, other “competitors” are offering glass AND metal and they make a lot of bold claims about their offerings.”

Yes, we are well aware of these systems and the statements made. Allow us to quickly debunk those statements:

- These companies do not produce their own glass. Many do not test for anti slip ratings, do not properly test for anti-slip ratings, or provide data to customers of their ratings…..and if they do their data proves to be the incorrect testing - which is a huge liability for all involved.

- Many do not produce their own metal either - they are simply a broker jobbing everything out.

- These companies offer an aluminum framing system and they tout how great it is and all of the benefits that it offers. The TRUTH is this aluminum system is NOT necessary. These companies have fooled the market into believing that an aluminum non-structural system is necessary for glass floors and this is not true. A glass floor can be glazed directly to the structural supports and this is what Jockimo recommends.

You see, these system still needs to be glazed onto the structural supports that you will need to supply. Some “competitor” literature even states in small type hidden in a corner “designed to work as a NON-Structural assembly…..”

Would you put a bathtub inside of a bathtub to take a bath?? Their “amazing” aluminum framing systems are unnecessary and a waste of $.

Our glass combined with our metal partners system is superior to any other product offering/solution on the market.

JGlass™ Anti-Scratch

Watch our JGlass™ Demo!Jockimo is proud to announce JGlass™ - our anti-scratch solution for glass flooring. This new technology is the first in the glass flooring industry and meets a growing requirement among architects and interior designers. JGlass™ can be applied to the entire family of Jockimo anti-slip glass flooring surfaces as well as their ThickGlass™ counter tops and vertical cast glass products. Here are the details on JGlass™:

Watch our JGlass™ Demo!Jockimo is proud to announce JGlass™ - our anti-scratch solution for glass flooring. This new technology is the first in the glass flooring industry and meets a growing requirement among architects and interior designers. JGlass™ can be applied to the entire family of Jockimo anti-slip glass flooring surfaces as well as their ThickGlass™ counter tops and vertical cast glass products. Here are the details on JGlass™:

- Highly water-repellent (hydrophobic), and so:

- Require less frequent cleanings

- Experience a reduction in mold and bacteria

- Easier to clean – eliminating the need for harsh chemical cleaners.

- Stain and graffiti resistant.

- Oil repellent.

- Scratch resistant.

- Impact resistant.

- Resistant to leaching of calcium and sodium (etching caused by hard water).

- At least 1,000 times more electrical resistant (additional electrical insulation).

- At least 20% more brilliant (shine in glass surfaces).

- Environmentally friendly.

How to Work with Us

As to where to start, we will need to receive a take off (quantities and sizes) from you as well as any plans that you can send. (You can fax or e-mail pdfs to us.) Please include any details of the structural support system for the flooring as well. You can email them to: This email address is being protected from spambots. You need JavaScript enabled to view it. We offer three major types of UL Approved glass flooring and we need to know which option you are interested in for this project - either Crystal Clear™, Ultimate Privacy™ or Ultimate Privacy Frost™. We also offer two different anti-slip surfaces.

Installation Instructions

Most installations will involve the use of silicone/rubber setting blocks in conjunction with liquid silicone when installing our glass flooring. The glass will be siliconed directly to the structural support system which in turn provides a secure and safe installation for all involved. We do NOT recommend ever drilling holes in glass flooring. Holes can weaken the glass and increases the chance of breakage. We recommend a non-acidic clear silicone. Please contact us for the recommended silicone to use on your project safe in conjunction with our lamination layer and in turn recommend: * Please note - using any non-recommend silicone will void the glass warranty.

The silicone setting strips should be glued to the steel substructure before the glass is set. The silicone setting blocks should be 60 - 70 shore. Various products can be used. CR Laurence has a product called PSB 250 which are 1/4" x whatever. The clear ones are 60 shore. Others will work as well. CR Laurence 1-800-421-6144.

There are two different ways to install setting blocks: 1.) Place a block every 6" - 12" around the perimeter on the support. 2.) Use a material that fully covers the support. The material can be cut to size and set in place. Which option to use ultimately is the decision of the glazier, GC, and end user/owner.

Cleaning & Maintenance

To obtain best results, a feather duster is ideal for regular day-to-day cleaning of glass. If a more thorough cleaning of glass is necessary, the following materials and methods should be used: Materials – Soft lint free cloth (do not use coarse brown paper towels), and a non-abrasive, non-ammonia glass cleaner. Avoid abrasive materials and solutions. Method – Spray the cloth lightly with cleaning solution. Dab the cloth softly on the glass surface to remove dust and lint. For more heavily soiled areas, use a light circular motion to remove dirt. Clean all accessible surfaces of the glass.

Glass, like all other functional products, will greatly benefit from a program of routine maintenance. While regular cleaning of the glass is the most obvious aspect of a maintenance regimen, it is also important to inspect the condition of adjacent materials such as grouts, adhesives, fasteners and hardware.

Architectural glass should be reviewed at least annually in order to ensure that related components are performing adequately.

Glossary of Terms

Following are a glossary of terms commonly used when describing glass flooring:

- Annealed - Annealed glass is glass without internal stresses caused by heat treatment (i.e. by rapid cooling, or by toughening or heat strengthening). Glass becomes annealed if it is heated above a transition point then allowed to cool slowly, without being quenched. Annealed glass breaks into large, jagged shards that can cause serious injury, and thus annealed glass is considered a hazard in architectural applications. Building codes in many parts of the world restrict the use of annealed glass in areas where there is a high risk of breakage and injury, for example in bathrooms, in door panels, fire exits and at low heights in schools or domestic houses.

- Tempered - Tempered glass is four to five times stronger than standard annealed glass and does not break into sharp shards when it fails. Tempered glass is manufactured through a process of extreme heating and rapid cooling, making it harder than normal glass. This heating process causes the glass to shatter into small oval-shaped pebbles when broken. This eliminates the danger of sharp edges. Due to this property, along with its strength, tempered glass is often referred to as "safety" glass.

- Laminated - Laminated glass is a type of safety glass that holds together when shattered. In the event of breakage, it is held in place by an interlayer between its two or more layers of glass. The interlayer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces. This produces a characteristic "spider web" cracking pattern when the impact is not enough to completely pierce the glass.

- Polished Edges - The edges of glass are often polished to remove irregular edges and provide a clean finished edge on the glass. Typically edges that are exposed and not captured by hardware are polished.